안녕하세요. 나우로보틱스 블로그 지기, 나우지기 입니다! 자동화와 관련한 수요가 나날히 늘어나고 있지만 선뜻 자동화를 바로 실행하기 어려워하는 곳도 적지 않은 것이 현실입니다. 그렇다면 자동화를 한다면 AMR 로봇과 비교해 어떤 점이 더 좋은 지를 파악하고 이해한다면 자동화 도입을 하는데 있어 좀 더 수월하게 의사결정을 내릴 수 있지 않을까요?

그래서 오늘은 자동화 시스템과 최근 창고 자동화와 관련해 크게 주목받고 있는 AMR 로봇을 도입하면 어떤 이점이 있는지를 외신 기사를 통해 살펴 보고자 합니다!

Automation Opportunity

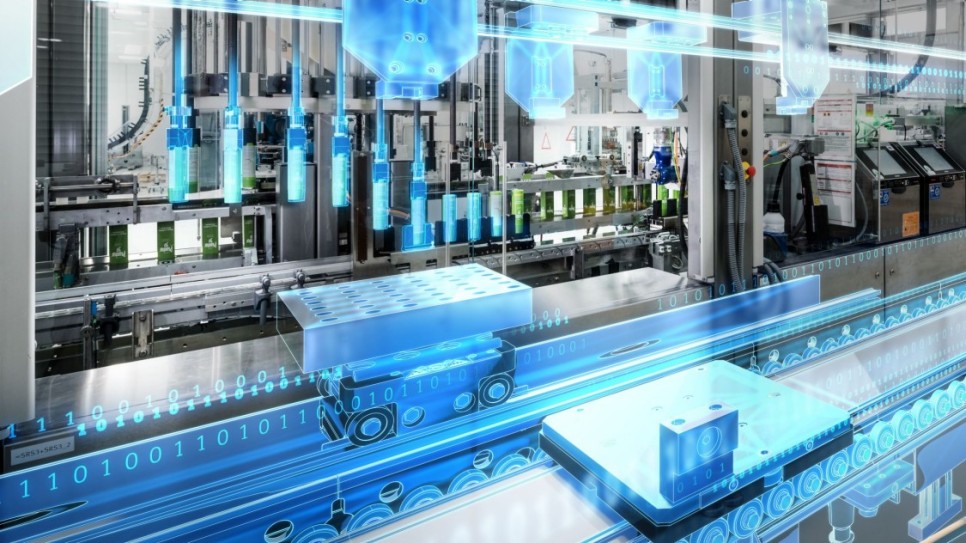

(E) Every manufacturing and logistics company is facing the same pressures, irrespective of size or longevity. Spiralling costs, supply chain disruption and a diminishing workforce are creating unprecedented challenges. For the larger businesses, the drive to automation is well established: in 2018, the global logistics automation market was valued at US$39.29 billion (£30.16 billion) and is expected to reach over US$121.3 billion (£93.11 billion) by 2027. And it is the demand for industrial robots that is driving much of that growth.

(K) 오늘 모든 제조와 물류회사는 회사의 규모, 기간 등과는 상관없이 똑 같은 문제에 직면해 있다. 급증하는 비용, 공급망 중단 및 인력감소 현상 등으로 전례없는 문제가 발생하고 있다. 2018년 전세계 물류 자동화 시장은 392억 9000만달러(301억 6000만파운드) 규모로 추정됐으며, 2027년까지 1213억 달러(931억 1000만 파운드) 규모까지 성장할 것으로 예상된다. 그 중심에는 산업용 로봇 수요가 있다.

(E) Too many smaller organisations, however, still believe that automation is simply an investment too far, especially when faced with so many escalating operational costs. On top of steeply increasing fuel and raw material costs, warehouses in Britain are paying up to 30% more to recruit staff, according to the UK Warehousing Association. As a result, few small businesses have the confidence to make a big capital investment, even if demand is increasing. But automation doesn’t have to be expensive – and it doesn’t even need to be a capital investment.

(K) 그러나 소규모 조직은 여전히 자동화는 운영 비용상승 대비해 투자비용이 크다고 생각한다. 영국에서는 연료비와 원자재 비용이 빠르게 증가하는 것 뿐만 아니라, 창고들의 직원을 모집하기 위해 최대 30%까지 더 많은 비용을 지불하고 있는 것으로 나타났다. 결과적으로, 수요가 증가하더라도 큰 자본 투자를 할 수 있는 중소기업은 거의 없다. 그러나 자동화는 비용이 많이 들 필요가 없으며 자본 투자일 필요도 없습니다.

(E) While a full, end to end automation project will demand time and commitment, one or two robots can be added to any warehouse or manufacturing business without the need for any disruption or even any custom IT integration. In one small scale trial, a warehouse opted to download orders onto a memory stick to provide the robot with a list of activities for the day. The robot works alongside existing employees, showing the business – and the workforce – just how easy and intuitive the automation process can be.

(K) 자동화 프로젝트를 하기에는 시간과 노력이 필요하지만, 기존의 시스템을 중단하거나 IT 통합 시스템 등이 없이 한 두대의 로봇만으로 모든 창고나 제조 비즈니스에 추가할 수 있다. 한 소규모 실험에서 어느 창고는 로봇에게 그날의 업무 목록을 제공하기 위해 메모리 스틱에 주문을 다운로드 하는 것을 선택했다. 이 로봇은 기존 직원들과 함께 업무를 하면서 자동화 프로세스가 얼마나 쉽고 직관적인지를 비즈니스 및 인력을 통해 보여줬다.

Accessible Robots

(E) Obviously, automation comes in many shapes and sizes. Within a warehouse operation, organisations can explore different techniques to improve picking performance and accuracy – such as pick to light and voice-activated systems. Within manufacturing, conveyors and scanners can help to improve inventory management and improve productivity. So where do AMRs fit in? Essentially, an AMR is a vehicle that uses onboard sensors and processors to autonomously move materials without the need for physical guides or markers. The AMR’s main components include a controller, computing unit, battery, motors, sensors, lights, sounds and camera.

(K) 자동화는 분명 다양한 모양과 크기에 맞춰 진행된다. 창고 운영을 하면서 조직은 음성 인식 시스템 등과 같은 프로그램을 도입해 다양한 기술을 탐색한다. 제조과정에서 컨베이어와 스캐너는 재고관리를 개선하고 생산성을 향상시키는데 도움이 된다. 그렇다면 AMR은 어디에 적합할까? 본질적으로 AMR은 물리적 가이드나 장치가 없어도 온보드 센서와 프로세서를 사용해 물질을 자율적으로 이동한다. AMR의 주요 구성 요소에는 컨트롤러, 컴퓨팅 유닛, 배터리, 모터, 센서, 조명, 소리 및 카메라가 포함된다.

A simple trial of one or two AMRs is quick to deploy, and answers in practice the many pressing automation questions, such as ‘How do robots work alongside people?’, ‘Where can they be used?’ ‘How often do they need charging?’.

(K) AMR 로봇 한 두대를 간단하게 테스트 해봄으로서 빠르고, 실제로 ‘로봇이 사람과 함께 어떻게 작동할까’, ‘로봇이 어디에 사용될 수 있을까’ ‘얼마나 자주 충전이 필요할까’와 같은 다양한 자동화 질문에 대한 답을 얻는다.

Robots in Practice

(E) So where might an AMR work best? Essentially, robots can minimise the time spent walking around the building – something that is particularly valuable within a warehouse environment. Staff can spend more time picking, simply taking the goods to the robot at the end of the aisle. The robot can then take a number of items to the next location, such as packing. In a manufacturing setting, a robot could take the finished goods to the stores, or bring raw parts from stores – after they have been manually quality checked by a skilled employee.

(K) 그렇다면 AMR은 어디에 가장 적합할까? 기본적으로 로봇은 건물 주변을 이동하는데 걸리는 시간을 줄여줄 수 있으며 이는 창고와 같은 곳에 특히 중요하다. 직원들은 복도 끝에 있는 로봇에 물건을 가져다 주면서 더 많은 시간을 다른 곳에 사용할 수 있다. 그런 다음 로봇은 포장 등 여러 업무를 다음 위치로 가져갈 수 있다. 제조 환경에서 로봇은 숙련된 작업자가 품질을 검사하고 난 후 완제품을 매장으로 이동시키거나 또는 원재료를 가져오기도 한다.

(E) This approach allows the business to make the best use of all resources. Use people in their areas of expertise, such as accurate, fast picking and quality checking; while using robots to complete repetitive tasks such as moving goods around the warehouse quickly and safely.

(K) 이러한 방식을 통해 기업은 모든 리소스를 최대한 활용한다. 정확하고 빠른 피킹 및 품질 확인과 같은 전문 인력을 활용해 로봇을 사용해 빠르고 안전하게 창고 주변 물품 이동과 같은 반복적인 작업을 완료한다.

(E) For an initial trial, there is no need for direct integration into the IT system. Information about what tasks to complete and when it can be provided by a small software link or a piece of hardware that identifies when an item is ready to be collected. It is a straightforward process to show the business – and employees – how and where automation and people can work side by side.

(K) 자동화 초기 단계에서 IT 시스템과 바로 통합(연계)할 필요는 없다. 항목을 수집할 준비가 된 시기를 식별하는 작은 소프트웨어 링크 또는 하드웨어에서 어떤 작업을 완료하고 언제 제공할 수 있는지 등을 정한다. 이 프로세스는 비즈니스와 작업자에게 자동화 시스템과 작업자가 함께 할 수 있는 방법과 장소를 보여준다.

Low-Cost Automation

(E) Obviously, the more a business automates, the greater the efficiencies gained. But even the smallest automation will deliver improvements. Adding a robot or two can allow a business to reallocate staff to more valuable areas and help to reduce the pressure on recruiting warehouse operatives.

(K) 비즈니스를 자동화 할 수 있도록 더 큰 효율성을 얻을 수 있는 것은 명확한 사실이다. 하지만 자동화를 소규모로 하더라도 개선효과를 얻을 수는 있다. 로봇을 한 두 대 추가하면 기업은 직원을 더욱 가치있는 업무에 배정하여 창고 인력 부담을 줄일 수 있다.

(E) With confidence in the technology and a real understanding of automation in practice, it is far easier for a business to consider where and when automation could fit. And for those companies still concerned about the level of investment, growing numbers of robots are now available on a rental model – even by the hour.

(K) 기술에 대한 확신과 자동화에 대한 이해를 통해 기업은 자동화를 어디에 하면 좋을지에 대한 위치와 시기를 고려하는 것이 훨씬 쉬워진다. 그리고 여전히 투자 수준에 대해 우려하고 있는 회사들을 위해, 더 많은 로봇이 심지어 시간 단위로도 대여 모델로 이용 가능하다.

(E) The concept of ‘robot as a service’ is hugely compelling for industries, such as logistics and manufacturing, where peaks and troughs in demand are hard to manage with a permanent workforce. With a couple of robots parked up, charged and ready to go, a business can be 100% in control of the cost, paying only for the hours used but with confidence that the capacity is available to cope with peaks in demand.

(K) 서비스용 로봇은 로봇 수요가 최고조에 달한 물류와 제조업과 같은 현장에서 상당히 매력적인 아이템이다. 몇 대의 로봇이 주차돼 있거나 충전돼 있고 바로 사용할 수 있는 상태이기 때문에 기업은 사용시간에 대해서만 비용을 100% 관리할 수 있지만, 수요가 최고조로 달할 때 용량을 사용할 수 있다는 확신을 갖고 비용을 관리할 수 있다.

(E) The key is to build that confidence, embark on a small scale trial and understand how AMRs work in any business, of any size, to create a successful, efficient hybrid workforce that can scale up and down in line with demand.

(K) 이러한 근거를 바탕으로 자동화에 대한 소규모 테스트와 운영을 시작해 AMR이 어떤 비즈니스, 어떤 규모에서 어떻게 작동하는지를 파악해 수요에 맞춰 확장 및 축소할 수 있는 성공적이고 효율적인 인력을 구축하는 것이 핵심이다.