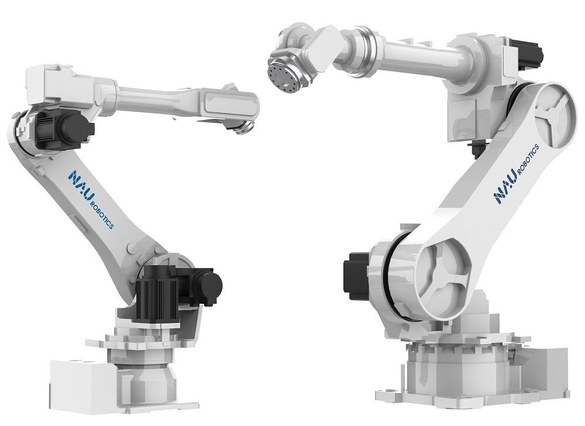

NAU Robotics announced on April 18 that it had released

multi-joint robots which have realized the secondary automation of plastic

injection. NURO X is a multi-axes robot which can execute operations like

cutting, loading and transporting which were difficult for the existing cartesian

robots in the plastic injection sites. A major feature of these new robots is

that they can conduct the insert and take-out processes within injection

machines, which are the most basic in the injection molding process, and then,

automation of diverse secondary operations.

Until now, cartesian robots have been used in injection

sites. In many cases, the stages of automation have been limited to the insert

and take-out operations. As the injection procedure and structure of molds have

become complicated, however, there were limitations to improve production

efficiency to apply automation to the primary operation for simply putting in

raw materials and taking out products.

An official of NAU Robotics explained, “The need to establish

procedures to do cutting as part of additional processing operations after

finishing the take-out process at an injection machine or connect with loading

and transporting has been increasing. NURO X has a wide range and is economical

because it can handle not only the basic insert and take-out but also the

secondary operations with automation.”

Besides, NAU Robotics applied UI and UX programming

developed by it to NURO X. It is more difficult and complicated to code

ordinary multi-joint robots than cartesian robots. In consequence, users have

experienced difficulties in operating them. NURO X, to which UI developed by

NAU Robotics was applied, can be developed with icon shape-based programming.

The purchasers can easily apply the robots and respond to field requests

rapidly.