Today, the industrial portal ‘Yeogie’ is publishing an interview with NAU Technics.

Whereas large enterprises in the industry of manufacturing robots realize the competitive robot prices by making robot hardware, small and medium-sized companies become system partners to execute system integration. While large companies lead mass-production of hardware, small and mid-sized firms develop and establish applications because they have a high understanding of site factors by industry.

In Japan, prominent large companies, such as first-generation robot makers Nachi-Fujikoshi and Kawasaki Robotics in the late 1960s, and Mitsubishi, Fanuc, Yaskawa, Denso and Toshiba, are producing robots for manufacturing and their system partners are at the forefront to lead the global market.

In Korea, Hyundai Heavy Industries formed a robot team in its welding technology research center in 1984 and started the operation of a robot assembly plant in 1986 based on technological partnership with Nachi-Fujikoshi, but it actually developed 6-axis vertical multi-joint robots, a unique model, in 1995. The company certainly performed well in the competition with global robot makers, but it still has many tasks to solve.

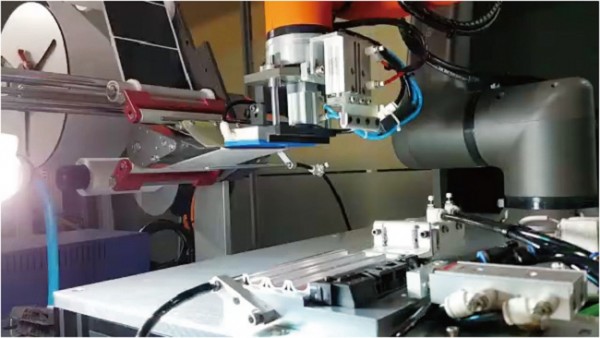

The collaborative robot industry has been rapidly emerging in recent years and Hanwha Techwin advanced into the collaborative robot business for the first time in Korea, preparing a basis to establish the market structure as in advanced nations. NAU Technics, a system partner of Hanwha Techwin, has successfully built collaborative robot applications in various industrial fields and has been trying to expand the market in 2018 by establishing diversified references.