Cartesian take-out robot

NURO

SERIES

The best NC-type handling all-axis servo

Cartesian take-out robots which lead the

efforts to make injection molding sites smart!

Nuro has perfectly complemented and overcome the limitations of Cartesian take-out robots which had been applied to the existing injection sites! Based on a design in a way to minimize space constraints through applying weight reduction and slimming, J motions are installed to overcome the limitations of the existing cartesian robots, in order to provide a faster injection take-out time cycle!

Equipped with Ethernet-based server technology, it is freely compatible with the server system, and the communication function mounted on the robot body is connected with the MES solution in order for production situations to be monitored continuously on a screen and the perfect process automation system to be materialized!

Nuro is adapted with our own software and teaching pendant developed by NAU ROBOTICS. It’s more convenient and help to work more easily compared to other robots. Every worker both novice label and master level could use easily the software for plastic injection molding manufacturing. It’ll provide the most optimized programming for you!

Light Weight and High Speed

With these robots, it will be possible to minimize space constraints and to increase the speed by applying them based on the light-weight and optimized design formulated considering the size and space of general injection molding sites.

J Motion

In order to enhance the efficiency of insert and take-out processes which are rapidly repeated due to the features of the injection molding process, the much faster injection molding take-out cycle time has been achieved through installing the J motion which overcomes the limitations of the movement of the existing cartesian take-out robot

Smart

In order to solve problems of the existing robot coating type, an operator screen which is simple and easy to use is provided, and the Ethernet-based server controlling technology which can be easily operated, low power consumption and modular joint design are applied.

3C

This is a smart system which can continuously check the production status through the screen by linking the communication function and the MES solution in the robot body and can be connected with other robots.

(However, it only has a monitoring function.)

Programming

The problems of cartesian take-out robot that exists on the market in which the robot program should be corrected and education by the manufacturer is required have been complemented to apply direct programming which the user can flexibly and easily apply.

Application Cases

Code Cases

Product Image

Robot Images

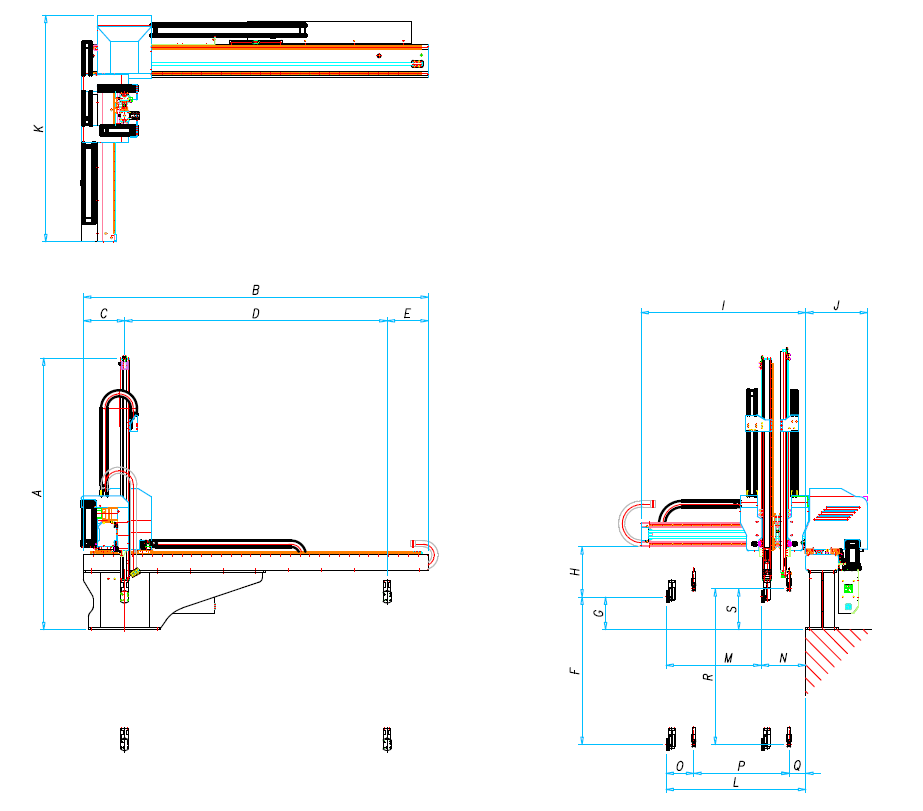

Specifications & Drawings

Spec & Drawing

| MODEL | DIMENSION | |||||||||||||||||

| A | B | C | D | E | F | G | H | I | J | L | M | N | O | P | Q | R | S | |

| NURO5-0811S | 1557 [1657] | 2102 | 251 | 1600 | 251 | 800 [900] [1100] | 200 | 306 | 1004 | 376 | 852 | 680 [680] [780] | 172 | - | - | - | - | - |

| NURO5-0811D | 1607 [1707] [1907] | 2102 | 251 | 1600 | 251 | 850 [950] [1150] | 200 | 306 | 1004 | 376 | 852 | 580 [580] [680] | 272 | 180 | 580 | 102 | 850 [950] [1100] | 250 |

| NURO10-1315S | 2271 [2471] | 2602 | 301 | 2000 | 301 | 1300 [1500] | 250 | 400 | 1355 | 427 | 1170 | 980 | 190 | - | - | - | - | - |

| NURO10-1315D | 2311 [2511] | 2602 | 301 | 2000 | 301 | 1350 [1550] | 250 | 400 | 1355 | 427 | 1170 | 810 | 360 | 232 | 810 | 128 | 1350 [1550] | 300 |

| NURO15-1618S | 2714 [2914] | 3062 | 381 | 2300 | 381 | 1600 [1800] | 300 | 480 | 1586 | 488 | 1407 | 1260 | 147 | - | - | - | - | - |

| NURO15-1618D | 2744 [2944] | 3062 | 381 | 2300 | 381 | 1650 [1850] | 300 | 480 | 1586 | 488 | 1407 | 1040 | 367 | 250 | 1040 | 117 | 1650 [1850] | 350 |

| NURO5-0811SII | 1225 [1275] [1375] | 2102 [2102] [2202] | 251 | 1600 | 251 [251] [351] | 800 [900] [1100] | 200 | 306 | 1004 [1054] [1154] | 376 [476] [476] | 852 [852] [952] | 680 [680] [780] | 172 | - | - | - | - | - |

| NURO5-0811DII | 1250 [1300] [1400] | 2102 [2102] [2202] | 251 | 1600 | 251 [251] [351] | 850 [950] [1150] | 200 | 306 | 1004 [1054] [1154] | 376 [476] [476] | 852 [852] [952] | 580 [580] [680] | 272 | 180 | 580 [580] [680] | 102 | 850 [950] [1150] | 250 |

| NURO10-1315SII | 1620 [1720] | 2602 | 301 | 2000 | 301 | 1300 [1500] | 250 | 400 | 1355 | 427 | 1170 | 980 | 190 | - | - | - | - | - |

| NURO10-1315DII | 1645 [1745] | 2602 | 301 | 2000 | 301 | 1350 [1550] | 250 | 400 | 1355 | 427 | 1170 | 810 | 360 | 232 | 810 | 128 | 1350 [1550] | 300 |

| NURO15-1618SII | 1880 [1980] | 3062 | 381 | 2300 | 381 | 1600 [1800] | 300 | 480 | 1586 | 488 | 1407 | 1260 | 147 | - | - | - | - | - |

| NURO15-1618DII | 1905 [2005] | 3062 | 381 | 2300 | 381 | 1650 [1850] | 300 | 480 | 1586 | 488 | 1407 | 1040 | 367 | 250 | 1040 | 117 | 1650 [1850] | 350 |

| NURO25-1620SII | 2020 [2220] | 3400 [3900] | 450 | 2500 [3000] | 450 | 1600 [2000] | 300 | 520 | 1940 | 550 | 1835 | 1500 | 343 | - | - | - | - | - |

| NURO50-2530SII | 3005 [3255] | 4510 [5010] | 1000 | 3500 [4000] | 805 | 2500 [3000] | 500 | 600 | 2680 | 693 | 2264 | 1700 | 574 | - | - | - | - | - |

| Model | 전후축(Y축) Crosswise(Y-axis) | 상하축(Z축) - Vertical(Z-axis) | 주행축(X축) - Traverse (X-axis) | 공기소모량 (Air Consumption) ℓ/Cycle(ANR) | 전원설비용량 (Power Consumption) (KVA) | 가반하중 (Payload) (Kg) | |||

| Stroke(mm) | Speed(m/s) | Stroke(mm) | Speed(m/s) | Stroke(mm) | Speed(m/s) | ||||

| NURO5-0811S | 680 [780] | 1.0 | 800 [900] [1100] | 2.5 | 1600 | 1.5 | 4.8 | 1.2 | 5 |

| NURO5-0811D | 580 [680] | 1.0 | 800[850] 900[950] 1100[1150] | 2.5 | 1.5 | 4.9 | 2.1 | ||

| NURO10-1315S | 980 | 1.0 | 1300 [1500] | 2.5 | 2000 | 1.5 | 4.9 | 2.0 | 10 |

| NURO10-1315D | 810 | 1.0 | 1300[1350] 1500[1550] | 2.5 | 1.5 | 5.0 | 2.9 | ||

| NURO15-1618S | 1260 | 1.0 | 1600 [1800] | 2.5 | 2300 | 1.5 | 4.9 | 3.5 | 15 |

| NURO15-1618D | 1040 | 1.0 | 1600[1650] 1800[1850] | 2.5 | 2500 | 1.5 | 5.0 | 4.5 | |

| NURO5-0811SII | 680 [780] | 1.0 | 800 [900] [1100] | 2.5 | 1600 | 1.5 | 4.8 | 1.2 | 5 |

| NURO5-0811DII | 580 [660] | 1.0 | 800[850] 900[950] 1000[1150] | 2.5 | 1.5 | 4.9 | 2.1 | ||

| NURO10-1315SII | 980 | 1.0 | 1300 [1500] | 2.5 | 2000 | 1.3 | 4.9 | 2.0 | 10 |

| NURO10-1315DII | 810 | 1.0 | 1300[1350] 1500[1550] | 2.5 | 1.3 | 5.0 | 2.9 | ||

| NURO15-1618SII | 1260 | 1.0 | 1600 [1800] | 2.5 | 2300 | 1.3 | 6.8 | 3.5 | 15 |

| NURO15-1618DII | 1040 | 1.0 | 1600[1650] 1800[1850] | 2.5 | 1.3 | 7.0 | 4.5 | ||

| NURO25-1620SII | 1500 | 1.0 | 1600 [2000] | 2.8 | 2500 | 1.3 | 45 | 3.4 | 25 |

| NURO50-2530SII | 1700 | 1.0 | 2500 [3000] | 2.4 | 3500 [4000] | 1.0 | 80 | 5.7 | 50 |

Application

Application

Intuitive User Interface

Designed in the intuitive UI type, instead of the existing difficult coding type, to be operated like cartesian take-out robots, even people who are not robot experts can easily operate them.

Optimized Software

It is possible to easily realize a robot system with the optimized programming through analyzing injection molding processes, such as taking out, insert, gate cutting and palletizing.

Easy Operation

Equipped with a touch screen, it is possible to quickly and easily confirm inputs through a really bright seven-inch screen.

Efficiency Maximization

The efficiency is maximized by resolving requirements of injection molding processes, such as multi-species small production and complicated molding structure, and various specifications of the working environment.