산업용 로봇부터 스마트 팩토리를 아우르는 로봇 전문 기업 (주)나우로보틱스가 지난 4월 신제품 생산라인 확충과 직원 사기 증진의 일환으로 신사옥 이전을 완료하고 글로벌 로봇 전문 기업으로서의 입지를 구축했다. (주)나우로보틱스가 구축한 신공장은 총 2개동으로 구성됐으며 이전 건물 면적 대비 이전보다 약 5배로 확대돼 향후 라인업 확충과 고객 대응 능력을 아우를 수 있게 됐다. 이번 신사옥 이전과 함께 동사는 로봇 라인업을 대거 출시했으며, 향후에는 자율주행로봇도 선보일 계획이다.

NAU Robotics, a robot company embracing industrial robots and smart factories, established a position as a global robot maker after establishing a new production line and moving into a new building as part of the enhancement of its employees’ morale in April. The new factory established by the company has two buildings and its size is about five times larger than the previous one. The lineup is going to be expanded so as to enhance the ability to respond to customers. With the office building relocation, the company has released a large robot lineup and has a plan to introduce self-driving robots.

NAU Robotics, a company specializing in the development of industrial robots and establishment of smart factories, completed the relocation to a new office building located in 449beon-gil 42, Aenggogae-ro, Namdong-gu, Incheon (Block 89 Lot 9 of Namdong Industrial Complex), preparing a foundation as a global robot maker.

With the building relocation, NAU Robotics can enhance its management capacity by improving the production efficiency and creating a comfortable working environment. A large meeting room was established on each floor of the new building, the company has equipped a system to prepare plans and activate information sharing among departments. The first floor has a cafeteria and various convenience facilities for employees’ welfare and the office space that is wider than the previous building is expected to greatly contribute to improving the working efficiency of employees.

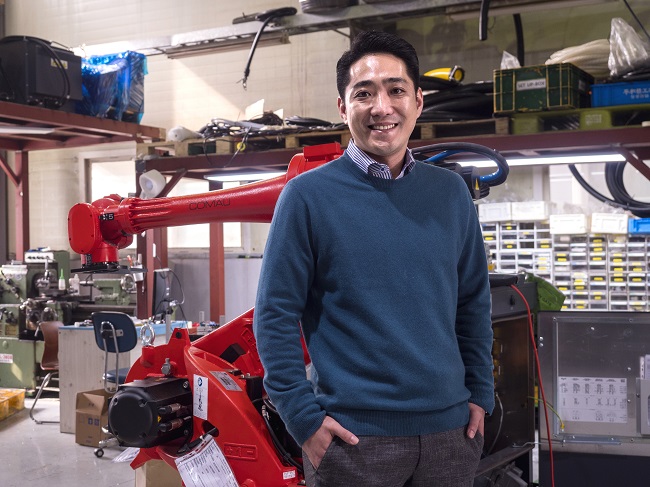

According to CEO Lee Jong-ju of NAU Robotics, “We have expanded production lines necessary for mass-production of new products and at the same time, made such a decision to increase the satisfaction of employees as a young enterprise. In the past, we increased the number of factories to two from one, but there still were limitations in terms of distance and space. To address such a problem, we built a factory building close to the office building, casting off limitations and enabling immediate responses.” He also said, “Most of our employees are professional technicians and engineers, so it is essential to continuously supply proper manpower like them. The relocation is mostly aimed at not only expanding our capacity but also supplying manpower to expand productivity and cultivating talented workers.”

NAU Robotics Embraces the Entire Robot Industry

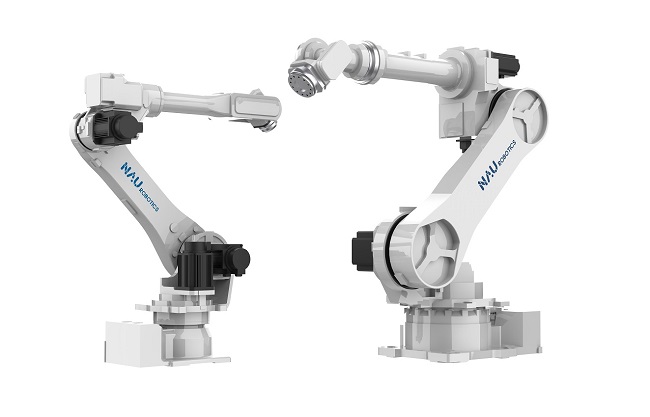

NAU Robotics has equipped a lineup embracing the entire robot industry, such as cartesian take-out robot (NURO), multi-axes robot NURO X and Scara robot NUCA. It is really meaningful that the company produced those three types of robots in particular. Such achievements show that the company has a pioneering vision to view the robot industry from various angles and expresses confidence as a result of possessing its own technology.

Lee explained, “When we were planning the initial robot lineup, we first produced robot controllers (teaching pendants), and accordingly we developed 6-axis multi-axes robots. In the process of producing those robots for take-out, this led to the expansion to cartesian take-out robots or Scara robots which are put into the lines. As our workers were talented people with expertise in the field of take-out robots, we had no troubles in expanding references like that,” adding, “we have focused on being reborn as a robot maker while continuously working on robot automation systems.”

The multi-joint robot NURO X, among products of NAU Robotics, in particular, was released as a model exclusively for handling, unlike ordinary general-purpose multi-axes robots, and is differentiated from existing equipment. In mid-to-large industries, such as automobiles and ships, molds have become more sophisticated and complicated, and accordingly, the market reaction is that it is complicated and troublesome to make products simply with take-out robots. In other words, the production sites, requiring more details, began to additionally require a series of procedures connected with operations like cutting, loading and transporting as part of post-processes from the increasingly complicated take-out procedure at injection machines. NURO X developed by NAU Robotics is considered a solution which can properly cope with such market needs.

CEO Lee stressed, “We thought the existing simple general-purpose equipment with operation difficulties in the market characterized by fierce price competition and many process changes had no merits, and as a result, we standardized the range of robot operation to execute even the post-processes. In addition, installing necessary software only for applications, these new robots are lighter than the existing ones, can be easily operated without separate multi-joint engineers and are favorable in terms of prices.”

Launching of AMR Imminent

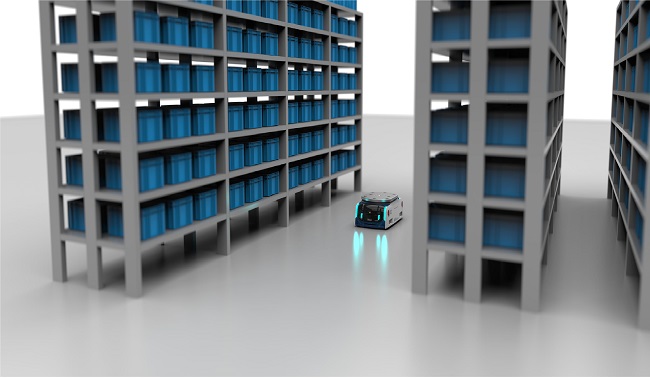

The largest goal of NAU Robotics embracing take-out, multi-joint, orthogonal and Scara robots and SI for this year is to launch AMR robots. The company plans to break away from generality and to introduce jacking-type and picking-type self-driving robots which can be applied to manufacturing only.

CEO Lee mentioned, “Rather than applying self-driving robots like AGV and AMR to various industries, including simply services, distribution logistics and manufacturing logistics, we are working focusing on making them for manufacturing. In order to realize logistics systematization in the manufacturing industry, it is essential to automate the front end of processes. We plan to realize it by supplying our robots to the spot. If the launching of logistics robots for manufacturing succeeds, we expect to naturally advance into the market of robots for logistics warehouses with excellent driving environment and little process change.” “We almost have reached the finishing stage and final testing is under way,” he added.

Listing Procedure, Step By Step!

After completing the office relocation in the first half of this year, NAU Robotics is going to pursue its listing on the KOSDAQ next year. NAU Robotics determined to proceed with the IPO and selected Hi Investment & Securities as the host in 2021, and attracted investment from Korea Credit Guarantee Fund in July last year. After this, the company received support by being selected as a First Penguin – where companies which show their potential as global leaders through sufficient technology and competitiveness are singled out.

CEO Lee said,

“Additionally, we will attract investment or go public next year. The schedule

will be somewhat flexible depending on the progress, but the listing will be

made without difficulties.”